Granulator

- Water-Cooling Strand Pelletizing LineWater-cooling strand pelletizing line consists of stainless steel water tank for cooling and strand pelletizer for PE, PVC, PA, PP, PS, PET and ABS cutting. Strand pelletizing is widely applied pelletizing process suitable for almost all materials. This process features simple equipment structure and convenient operation and maintenance. When pelletizing is performed in cold condition, pellets sticking can be avoided...

- Air-Cooling Hot-Face Pelletizing LineAir-cooling hot-face pelletizing line is designed for any pelletizing process of some polymers, including PVC, LLDPE, masterbatch, highly filled calcium carbonate masterbatch, degradable masterbatch, carbon black masterbatch, and so on. This pelletizing device could avoid moisture involved during pelletization process with replacing of air cooling. The main...

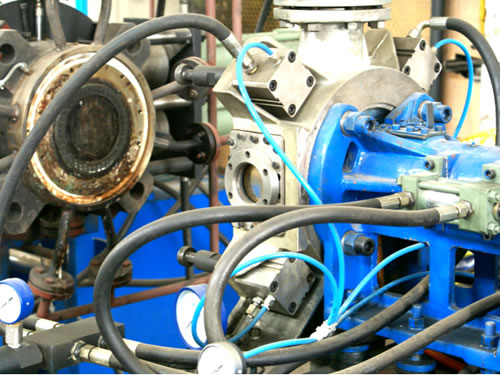

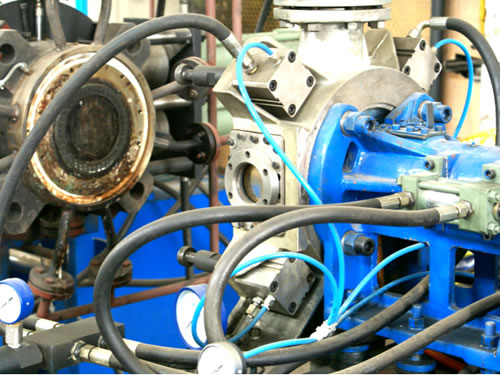

- Underwater Pelletizing LineUnderwater pelletizing line mainly includes electrical control system, melt pump, cutting die device, collector, hydraulic control system and centrifugal hydroextractor. Underwater pelletizer is suitable for pelletizing most thermoplastics. It is typically used for the processing of sticky products, PE, PP, PS, ABS, and so on. In addition, the underwater pelletizing line is an ...

Description:

Granulator is a general device for cutting strip or sheet plastic into granular materials. The pelletizer is a new generation of particle device. It is mainly composed of feeding, mixing, granulation, transmission and lubrication systems. It is specially designed with a filter screen that can filter materials carefully. Besides, the friction filter rod can break sturdy particles to be filtered. It can replace the swing particle machine. Granulator is widely used in the pharmaceutical, chemical and food industries, but this pelletizer is not applicable for semi-solid and fluid materials.

Features:

1. With a reasonable structure, our granulators can pelletize materials without leakage.

2. Rotary cutter employs carbide hob with high wear resistance. Lantytk® pelletizers adopt gearless design and belt drive, which can effectively reduce the operation noise.

3. Owning independent electrical box, it is convenient, safe and practical.

Classification of Granulator:

1. Water-Cooling Strand Pelletizing Line

2. Air-Cooling Hot-Face Pelletizing Line

3. Underwater Pelletizing Line

Note for Use:

When the granulator is in operation, do not touch the feed port, outlet, belt, gear and other rotating parts. Before using, users should inject some lubricating oil into the pelletizer so as to avoid damage.

Lantytk® Corp is a professional manufacturer and supplier of granulators in China. In addition to this pelletizer, we also specialize in producing twin screw extruder, screw feeder, electronic control system, some auxiliary equipment, and so on. With reliable quality control system, our products have passed CE and ISO9000 certification. Our granulators are exported to the United States, Germany, Japan, Denmark, Poland, Turkey, Morocco, Russia, India, Malaysia, Indonesia, Vietnam, Thailand and many other countries.