In 1965, our company developed twin screw extruder test bench (diameter: 51 or 75 mm) specially used for SBR and BR.

In 1970, we developed UHMW polyisobutene twin screw polymerization reactor.

In 1975, SLJ-150-132 and SLJ-31 combined extruder was put into pelletizing ABS wet powders.

In 1978, it won the National Scientific and Tech Conference Award, Gansu Province Significant Scientific Achievement Award and Ministry of Chemical Industry Significant Scientific Achievement Award. In 1987, it gained the national third-class invention award.

In 1978, Lantytk® developed STJ-80/100 single or two-stage screw extruders used to pelletize ABS wet powders. In 1980, it won the New Product Award from Lanzhou Petrochemical Corporation.

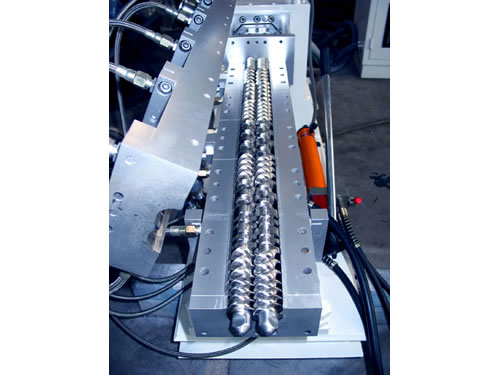

In 1979, our company developed the first SHJ-30 lab-used twin screw extruder in China. In 1989, it obtained Third Prize for Scientific Advancement awarded by the Ministry of Chemical.

In 1980, we developed the STJ-55/65 single or twin screw extruder. In 1981, ZFJ-36/28 evaporating twin screw extruder and SDJ-57/30 huge-degassing twin screw extruder were produced. In 1986, Lantytk® got the national sixth five-year plan scientific and technological project honor.

In 1984, SSF-60/28 twin screw PC condensation polymerization reactor was developed. In 1988, it passed the certification from Shanghai Committee of Science and Technology.

In 1985, Lantytk® developed the SHJ-68 twin screw compounding extruder. In 1991, we gained Second Prize for Scientific Advancement Award of Gansu province.

In 1987, SHJ-72 twin screw compounding extruder came into being. In 1992, we won Third Prize for Scientific Advancement Award of Nanjing city and Forth Prize for Scientific Advancement Award of Jiangsu province.

In 1989, our company undertook national key enterprises development project (design of SSF-175/35 twin screw PC condensation polymerization reactor).

In 1990, the second generation SHJ-68A twin screw compounding extruder was successfully developed. In 1995, it won the state-level key new product project award.

In 1991, our company was in charge of drafting and developing JB/T/5420-91 (co-rotating twin screw extruder) and JB/T5417-91 (plastic degassing twin screw extruder) industrial standard.

In 1995, SHJ-78 twin screw extruder with new driving mode was developed. The SHJ-68 twin screw extruder was awarded as National New Product.

In 1996, we produced the SHJ-58 twin screw extruder. It was extensively used in material cross-linking and foaming. Cantilever pelletizer was also produced.

In 1997, SHJ-92 twin screw extruder was put into use.

In 1998, SHJ-48 twin screw extruder (lab-used or production used) came into being. The wear-resisting technology passed the certification from the related department. Our company was approved as the technical support unit of co-rotating twin screw extruder by Ministry of Science and Technology.

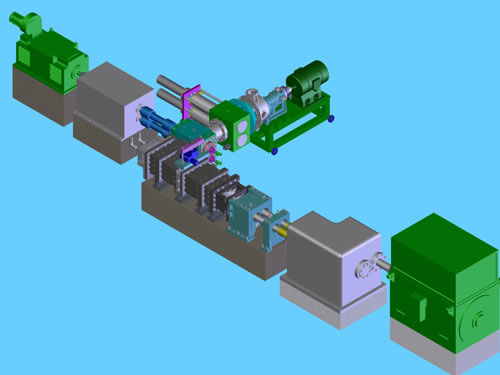

In 1999, we developed the SHJ-92 thermosetting phenolic moulding compounding twin screw extruder with wearable liner (adopting PCC control system). SHJ series extruders were certificated as “High-Quality High-Tech Product” by French Technology Quality Supervision Committee and were recommended to EU. We also produce the STJ-78/180 single or twin screw combined type extruder used for thermo sensitive plastics and chemical cross-linking plastics.

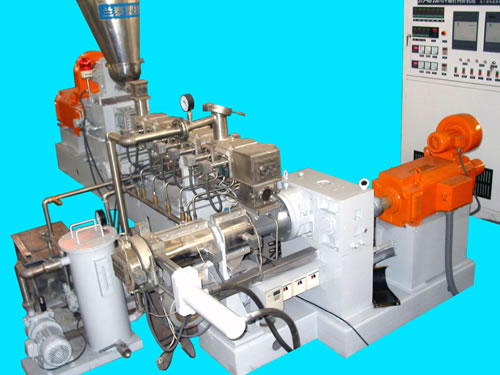

In 2000, our company developed the SHJ-92 extruder with high torque and high performance (280 Kw, 500rpm). It was the highest tech product at that time. We also produce the long L/D STJ-58/120 two-stage extruder, SHJ-78 thermosetting epoxy electric sealing material compounding extruder, SHJ-68B thermosol rotating hob pelletizer and water/pellet separator. We also revised the industrial standard of co-rotating twin screw extruder. Our products passed ISO9001 international quality system authentication. SHJ series products were recognized as “the Jiangsu Market Customer Satisfaction Product” by Jiangsu Quality Management Association. The SPJ-78, SPJ-92 and SPJ-132 twin screw extruders filled the twin screw extruder gap in China thermosetting plastics field. The forced feeding system was successfully used in the twin screw thermosetting extruder.

In 2001, we developed the SHJ-92 co-rotating twin screw compounding extruder with high torque.

This product is exported to Indonesia. The output can reach 1100 kg/hr, power 355 Kw and speed is 500 rpm. It is the highest tech product in China. We also produce double channel hydraulic screen changer. Our company undertook Sinopec’s continuous extruder developing project.

In 2002, we undertook Sinopec’s screw extrusion process and equipment development. We were in charge of designing and developing large granulators. The co-rotating twin screw compounding extruder was awarded as the state-level key new product.

In 2003, Lantytk® developed the 150mm counter-rotating twin screw extruder used for thermo sensitive plastics. Our company also undertook the national innovation fund project “high-speed high-performance co-rotating twin screw extruder” and drafted industrial standard of strand pelletizer.

In 2004, we developed the SHJ-18 lab-used twin screw extruder and the first SPJ-48 co-rotating twin screw extruder. Our company undertook the development of new polymer material twin screw extruder technology and equipment. We also revised the industrial standard of plastics extruding and pelletizing unit. Lantytk® developed a new type quick disassembling double brace pelletizer and multi-functional big L/D DJ-30 single screw extruding line.

In 2005, PET three-layer single screw extruding line has been exported to UAE. Our company developed the first high filling EVA sheet extruding line in China. SHJ-30 lab-used twin screw extruder was developed and widely used in the institute and university. 100000MT/Year double-shaft continuous compounder was designed. Besides, we also drafted the industry standard “Plastic Degassing Extruder”.

In 2006, our company developed China first 20000MT/Year PP twin screw compounding extrusion and pelletizing line. ABS reacting extruder was also developed. Two-stage twin or single screw extruding and pelletizing line was honored as “National Important New Product”. Lantytk® also undertook Gansu innovation fund project “Thermosetting Resin Special Compounding Extruder”.

In 2007, our company took charge of the innovation fund project of Science and Tech Department to develop “Thermosetting Resin Special Compounding Extruder”. We also undertook Gansu important project to develop the “20000Mt/Year PP Post-Processing Complete Technology and Equipment” and important project of SINOPEC to develop “200000MT/Year Large-Scale Extruding and Pelletizing Line”.

In 2008, we undertook the important project of SINOPEC to develop “Para Aramid Reactive Twin Screw Extruder System” and develop “Large-Scale Compounding and Pelletizing System” of Scientific Research Institute Technology R&D Fund Project. 10000MT/Year twin screw compounding extruding and pelletizing test bench was designed and put into use. STJ-132/250 two-stage PVC sheet extruder unit was developed. Besides, our company also organized Gansu Polymer Compounding Tech. and Equipment R&D center.

In 2009, our company took charge of the science and technology project of SINOPEC to develop “20000MT/Year Butyl Benzene Resin Direct Venting Extruder Unit”. Multiple twin screw extruders were successfully used in BOPP extruding line. We successfully developed the double-shaft pre-reacting equipment. Our company was honored as the “Conquer Difficulty Team” by Lanzhou SINOPEC Metallurgical Coal Union. We also developed 1000MT/Year and 10000MT/Year underwater pelletizers. Our company invested Nanjing processing production base and started construction.