Twin Screw Extruder

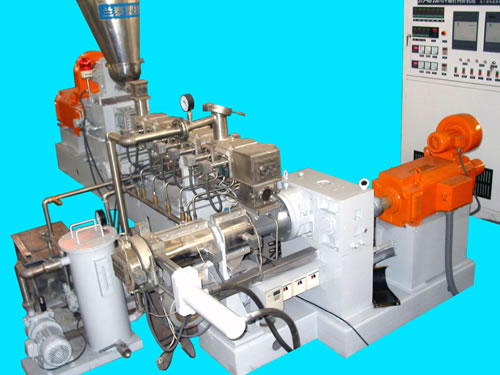

- SHJ Series Twin-Screw Compounding ExtruderThe SHJ twin-screw compounding extruder has screw threads made of high grade steel with a five-axis machining tool to reduce clearance and wear. This twin screw extruder is equipped with PLC controllers and high-level touch screen panels for manual or automatic operations. The extruder’s operating parameters are input and displayed on the touch panel...

- SSJ Series Twin Shaft Continuous MixerThe SSJ twin shaft continuous mixer is a powerful and reliable solution for continuous mixing processes, particularly those with coarse aggregates. This dual-shaft continuous mixer is especially suitable for producing mineral mixtures, RCC (Roller Compacted Concrete), landfill liners, lean concrete, heavy concrete and dry mixtures, and so on. SSJ series twin shaft ...

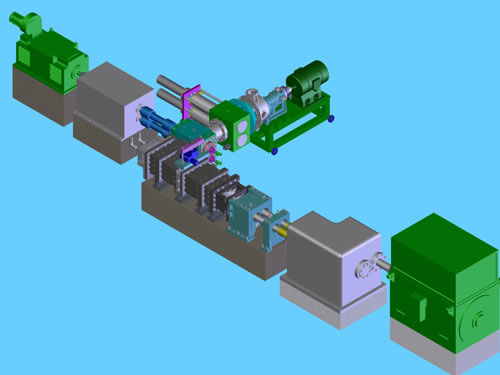

- STJ Series Two-Stage Compounding ExtruderSTJ series two-stage compounding extruder consists of two processing stages. The first stage is a SHJ twin-screw compounding extruder without die head. Through the combination of barrel and screw, this two stage extruder can exert its strong ability to make the thermo sensibility material (like PVC) melting, compounding, disturbing and decentralizing...

- STJ Series Twin Screw Extrusion Granulation UnitSTJ series twin screw extrusion granulation unit is a highly efficient agglomerating and extruding equipment. It consists of feeding system, twin screw extruder, pelletizing system and auxiliaries. Using PVC powder as its raw material, this plastic extrusion granulation machine is extensively used in many fields. It can be applied to produce plastic granules such as PVC...

- SPJ Series Co-Rotating Twin Screw ExtruderThe SPJ series co-rotating twin screw extruders are proven for the efficient, reliable and economic mixing, devolatilization and direct extrusion of wood and natural fiber plastic composites, such as phenolic molding plastic, epoxy electric sealing material, powder coating and other thermosetting resin ingredients. This twin screw extrusion equipment finds a wide variety...

- SFJ Series Twin-Screw Reactive ExtruderSFJ twin-screw reactive extrusion machine is a kind of special new product developed by JINGGONG Institute in recent years. This twin screw extruder is mainly used for reactive extrusion of various polymers. Recently, our company has made a lot of experimental studies for reactive extrusion. We have successfully designed and manufactured various twin-screw reactive...

- SZJ Series Twin-Screw Venting ExtruderSZJ twin-screw venting extruder is mainly used for devolatilization and concentration of various polymers. Our company has successfully developed fluoroplastics devolatilization, PVB devolatilization, butadiene-styrene resin devolatilization and many other special twin screw extruders. The butadiene-styrene resin venting extruder fills the domestic gaps and greatly enhances the level of China ...

Description:

Twin screw extruders is suitable for matching with production line of plastic pipe, plate, profile and others. This extrusion machine possesses advantages such as forced extruding, high quality, wide adaptability, long service life, low shearing speed, hard decomposition, good compounding and plasticization effect, direct shaping of powder materials, and so on. Twin screw extruders are extensively used for mixing, compounding or reacting polymeric materials. The twin screw extrusion machine is designed specifically with high flexibility. Thanks to the great variety of series and versions available for twin screw extruders, Lantytk® can always offer a system solution tailored to customers’ specific products and process requirements.

Features:

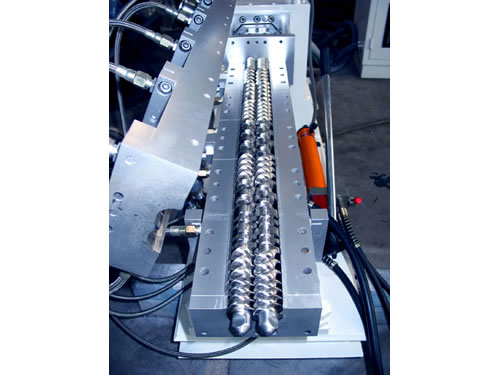

1. Due to the easy opening of this extrusion machine, we can directly find the wearing parts, further repair or change them to avoid unnecessary waste.

2. When manufacturing master batch, extruders often need to change color. When changing color, common extruders always use lots of cleaning materials and time. However, our twin screw extruders take less time to open the cylinder for manual cleaning, which can expend less or not use any cleaning materials to reduce production cost.

3. When repaired, the heating and cooling system of common twin screw extrusion machines must be removed to pull out the screw. While for Lantytk® twin screw extruders, we only need to loosen several bolts, move the handle device of worm gear case, and to open the upper half of the cylinder for repairing. This can save repairing time and reduce labor strength.

4. Our twin screw extrusion machines possess high torque and high revolving speed.

5. Lantytk® twin screw extruders cover a wide range of applications. They can be applicable to a variety of materials processing.

6. Twin screw extrusion machines have the advantages of high yield, high quality and high efficiency.

Classification of Twin Screw Extruder:

1. SHJ Series Twin-Screw Compounding Extruder

2. SSJ Series Twin Shaft Continuous Mixer

3. STJ Series Two-Stage Combination Compounding Extruder

4. STJ Series Twin Screw Plastic Extrusion Granulation Unit

5. SPJ Series Co-Rotating Twin Screw Extruder

6. SFJ Series Twin-Screw Reacting Extruder

7. SZJ Series Twin-Screw Venting Extruder

Lantytk® Corp is the birthplace of twin screw extruders in China. We have been researching and developing twin screw extrusion machines for more than 50 years. In addition, we also produce screw feeder, granulator, electronic control system, some auxiliary equipment, and so on. With reliable quality control system, our products have passed CE and ISO9000 certification. They are exported to the United States, Germany, Japan, Denmark, Poland, Turkey, Morocco, Russia, India, Malaysia, Indonesia, Vietnam, Thailand, etc.